Engineering

Espytes's comprehensive engineering team has the following characteristics:

- Engineers with the highest qualifications and extensive experience in developing special parts or custom projects.

- Wide knowledge of materials, tolerance values and geometries which, by respecting the project's characteristics with regard to physical, technical and functional properties of the parts, leads us to make substantial improvements in cost savings, which are felt by our clients.

- 2-D and 3-D design software to adapt projects to your functionality needs.

- Simulation software (finite element calculation) which allows us to anticipate potential improvements to be made before products enter into production, thus achieving maximum effectiveness and efficiency in project development.

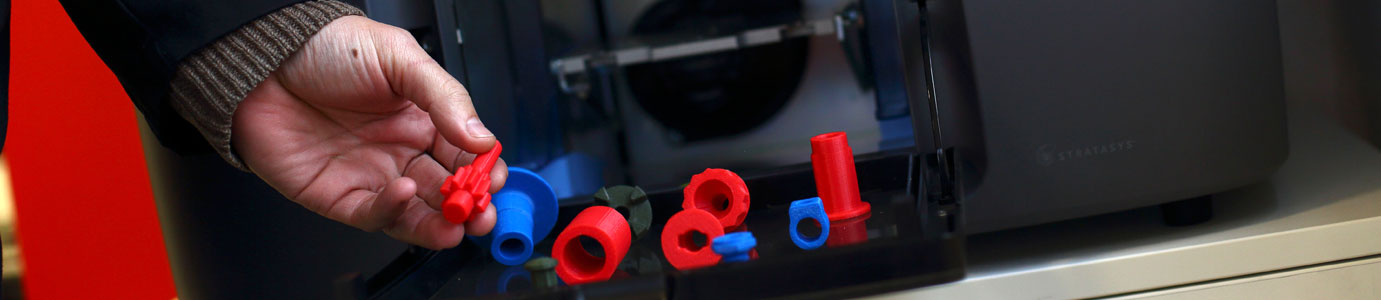

- 3-D printing which, together with the above means, allows for precise knowledge of the final product and all manufacturing steps before entering the production phase, therefore saving costs and improving the effectiveness of the entire manufacturing process.

In order to meet market needs, and to be able to reach maximum quality levels, our R&D&I department combines application of the above-mentioned advanced technological tools with our own know-how in the design of processes and tools.

Our constant commitment to R&D&I makes us grow and improve more and more each day, providing solutions to the stringent needs of custom cold-forming projects.

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

-

Click to open image!

Click to open image!

Click to open image!

Click to open image!

View the embedded image gallery online at:

http://www.espytes.com/en/engineering#sigProId36107d7f44

http://www.espytes.com/en/engineering#sigProId36107d7f44