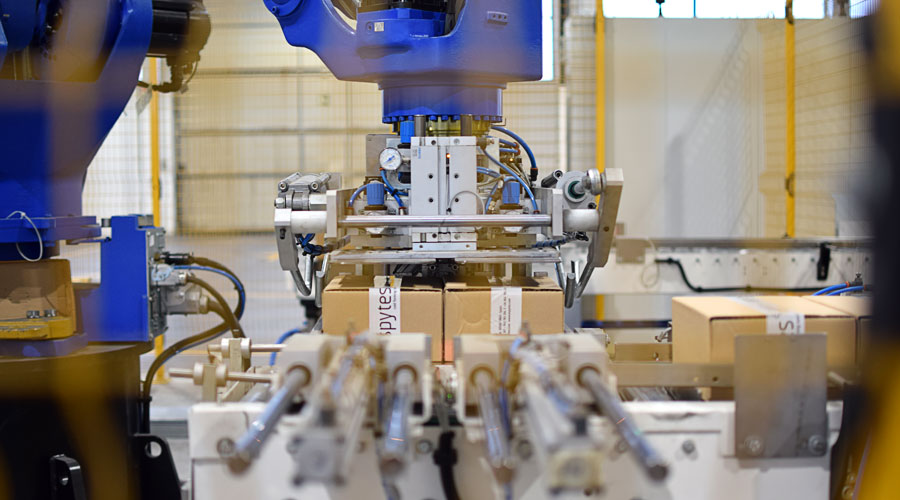

Espytes has a high-capacity automated robotic logistics centre. We focus on our customers’ projects, making sure their production lines never stop and that they have their products when they need them.

Our picking capacity is 275,000,000 units for all the parts we sell and 30,000,000 units for parts in stock. Our automatic machines can process up to 300 parts per minute and our annual picking volume is 150,000,000 parts.

Our cutting-edge logistics system enables efficient inventory and transportation management for our products. From extrusion manufacturing and cold stamping of studs, bolts and special parts to the final delivery to customers, our system ensures that each stage of the process is carried out efficiently and is problem-free. We use cutting-edge technology for real-time monitoring and tracking of our products, meaning we can make quick, accurate decisions to guarantee customer satisfaction.

Our company also has a perfectly organised team of professionals to meet the needs of customers anywhere in the world, thanks to our extensive sales and logistics network. Espytes exports over 80% of its production via its extensive distributor network.

Our processes are designed to guarantee speedy, efficient product delivery. From receipt and storage of raw materials to dispatch of finished products, our team works tirelessly to ensure each stage of the process runs smoothly.

We spare no effort to constantly optimise our inventory management, achieve more efficient control of our production line, improve the goods movement at our warehouses and automate our distribution operations to provide an exceptional service to customers, assuring their satisfaction every step of the way.